Laying Accessories

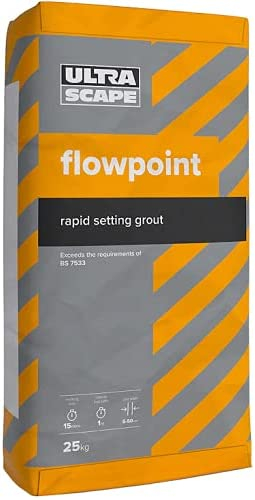

We stock paving grout, slurry primers, tile spacers, adhesives and cleaning agents and sealers to help you complete the installation of your project to the best possible finish for installing Natural Stone Paving

Speak to a member of our friendly sales team today on 01482 688008 or Email sales@meltonstone.co.uk

Laying Accessories

What is slurry primer and why do I need it?

Slurry primer, also known as bonding slurry or priming slurry, is a thin layer of cementitious material mixed with water that is applied to a substrate or base before installing tiles, paving stones, or other types of masonry materials. The purpose of using a slurry primer is to enhance adhesion between the substrate and the material being installed.

Here are a few reasons why you might consider using slurry primer:

1.Improved bond: Slurry primer helps create a strong bond between the substrate and the material being installed, such as tiles or paving stones. It fills in any irregularities or pores on the substrate surface, providing a better surface for the material to adhere to.

2.Reducing water absorption: Slurry primer can help reduce the absorbency of the substrate, particularly in cases where the substrate is highly porous or prone to moisture penetration. By applying a slurry primer, you create a barrier that minimizes water absorption, protecting the substrate and enhancing the bond.

3.Stabilizing the substrate: Slurry primer can help stabilize the substrate by providing a uniform surface and preventing differential movement between the substrate and the material being installed. This can be particularly important in situations where the substrate has uneven or weak areas.

4.Enhancing performance: Using a slurry primer can contribute to the long-term performance of the installation. It can reduce the risk of tile or paving stone movement, cracking, or delamination, ensuring a more durable and reliable result.

It's important to note that the need for slurry primer can depend on factors such as the type of material being installed, the characteristics of the substrate, and the manufacturer's recommendations. Different materials and substrates may have specific requirements regarding priming or bonding. Always refer to the manufacturer's guidelines or technical data sheets for the specific materials you are using, as they will provide the most accurate and reliable instructions for priming and installation.

Consulting with professionals, such as manufacturers, suppliers, or experienced installers, can also provide valuable guidance based on their expertise and knowledge of the specific materials and installation requirements.

Should I use priming slurry on sandstone pavers?

Using a priming slurry on sandstone pavers is not a common practice and is typically not necessary for standard installations. Sandstone pavers can generally be installed directly onto a suitable base or substrate without the use of a priming slurry. The natural texture and porosity of sandstone allow for good adhesion when using the appropriate installation methods.

However, there may be specific situations or circumstances where using a priming slurry on sandstone pavers could be beneficial. For example, if you are working with particularly smooth or non-porous sandstone, or if you are installing the pavers in vertical or overhead applications, a priming slurry might help enhance the bond and stability of the pavers.

If you are considering using a priming slurry on sandstone pavers, it is advisable to consult with the manufacturer or supplier of the sandstone pavers for their specific recommendations. They can provide guidance based on the characteristics of the sandstone and the installation requirements.

In general, proper surface preparation, including ensuring a clean and level substrate, is crucial for a successful sandstone paving installation. Following the manufacturer's guidelines, using the appropriate adhesive or mortar, and ensuring the pavers are installed with adequate joint spacing will contribute to a durable and visually appealing result.