Laying Accessories

To Install Limestone Natural Paving, you will need the relevant products to complete the job.

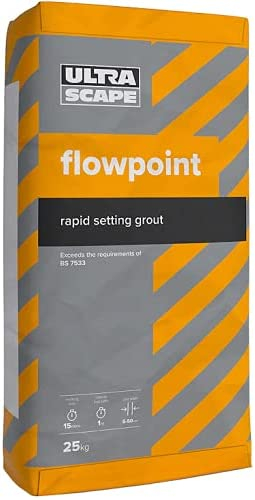

We stock paving grout, slurry primers, tile spacers, adhesives and cleaning agents and sealers to help you complete the installation of your project to the best possible finish.

Speak to a member of our friendly sales team today on 01482 688008 or Email sales@meltonstone.co.uk

Laying Accessories

What is Slurry Primer?

Installing Porcelain Paving is a slightly different process to other paving styles due to some key characteristics.

Porcelain Paving is great at being stain-resistant, anti-slip and low maintenance meaning that it will look and stay clean, with care, for years. But compared to other popular paving styles, including Indian Sandstone, Porcelain has an exceptionally low level of water absorption, which means it will not draw moisture to the same level.

However, this means when laying the porcelain paving, it won’t absorb much from the bedding mortar naturally but, with the help of ‘Slurry Primer’, a strong bond is created between the mortar bed and tile to help it stay in place, not lift over time and maintain its structural integrity.

Does brush in resin grout set solid?

Brush-in resin grout typically sets to a solid state, providing stability and durability to the paved area. Resin grout is designed to cure and harden, creating a solid bond between the paving slabs or tiles. Here's what you need to know about the setting characteristics of brush-in resin grout:

1.Curing time: The exact curing time for resin grout can vary depending on factors such as temperature, humidity, and the specific product used. Typically, resin grout will begin to set within a few hours after application, and full curing can take anywhere from 24 to 48 hours or longer. It's important to refer to the manufacturer's instructions for the specific product you are using to determine the recommended curing time.

2.Flexibility: Resin grout is designed to have a degree of flexibility to accommodate slight movements and shifts in the paving surface. This flexibility helps to prevent cracking or dislodgement of the grout when the pavers expand or contract due to temperature changes or ground movement.

3.Strength and stability: Once fully cured, resin grout provides strength and stability to the paved area. It forms a solid bond between the paving slabs, helping to distribute loads and maintain the overall structural integrity of the installation. This solid setting ensures that the grout remains in place and prevents shifting or movement of the pavers.

4.Resistance to water and weathering: Resin grout is typically water-resistant and can withstand exposure to moisture, rain, and temperature fluctuations without significant degradation. This resistance to water and weathering helps maintain the solidity and durability of the grout over time.

Proper installation, including following the manufacturer's instructions and using the correct mixing ratios, is crucial for achieving the desired solid setting and optimal performance of the resin grout. It's also important to allow sufficient curing time and avoid subjecting the grout to heavy loads or excessive traffic until it has fully cured.

Always refer to the specific manufacturer's instructions and guidelines provided with the resin grout product you are using for the most accurate and up-to-date information on its setting characteristics and recommended curing time.

Is slurry primer important for landscapers?

Slurry primer is an important tool for landscapers, especially when working with certain types of paving materials or in specific situations. Here are a few reasons why slurry primer may be beneficial for landscapers:

1.Enhancing bond and adhesion: Slurry primer is applied to the surface before laying the paving material and acts as a bonding agent. It helps improve the adhesion between the substrate and the paving material, ensuring a stronger bond. This is particularly useful when working with materials that may have lower inherent adhesion properties or when laying pavers on challenging surfaces.

2.Preventing efflorescence: Efflorescence is the white powdery substance that can appear on the surface of pavers due to the migration of salts within the material. Slurry primer can help reduce the risk of efflorescence by sealing the surface and preventing the migration of salts, ensuring a cleaner and more visually appealing paved area.

3.Stabilizing the substrate: In some cases, the substrate or base may have uneven or weak areas. Slurry primer can help stabilize the substrate by filling in gaps, cracks, or irregularities. This creates a more level and stable surface for the pavers, reducing the risk of shifting or settling over time.

While slurry primer can offer these benefits, it's important to note that it may not be necessary or suitable for all paving projects. The need for slurry primer can depend on factors such as the type of paving material, the condition of the substrate, and the specific requirements of the project.

As a landscaper, it's important to assess each project individually and consider factors such as the type of paving material being used, the condition of the substrate, and the recommendations of the manufacturer or supplier. Consult with professionals, such as manufacturers, suppliers, or experienced installers, who can provide guidance on whether slurry primer is necessary or beneficial for your specific project.

Can I make my own priming slurry?

Yes, you can make your own priming slurry for paving if you prefer to do so. However, it is not recommended as there are specific priming slurries that have different additives that create a more superior bond between the paving slab and the mortar bed.