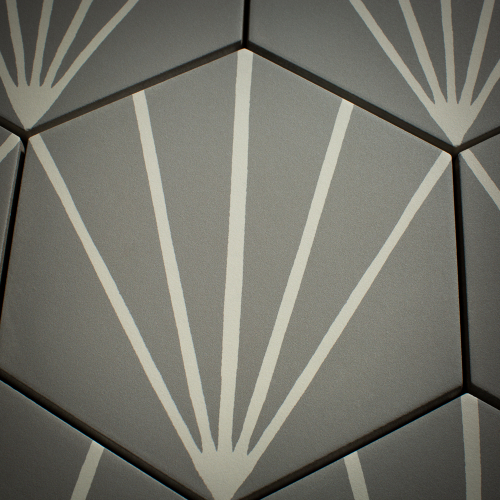

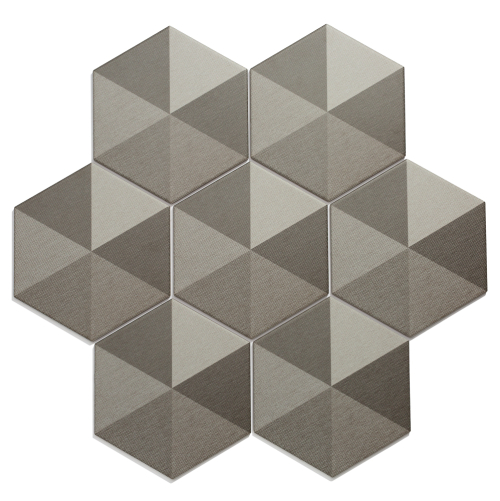

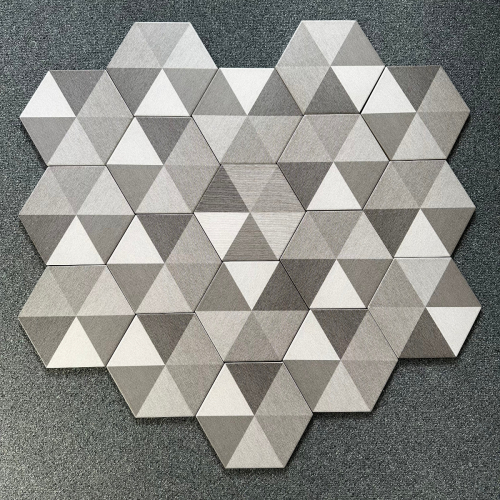

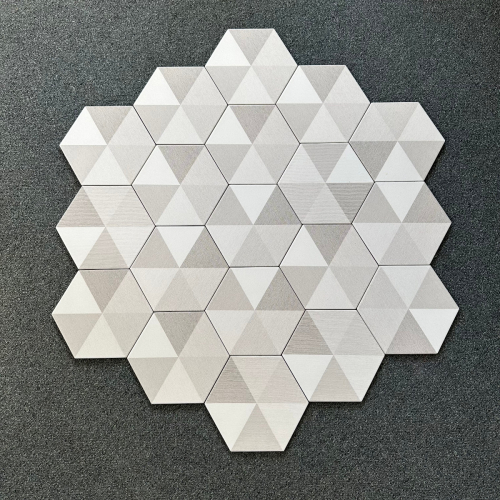

Tiles

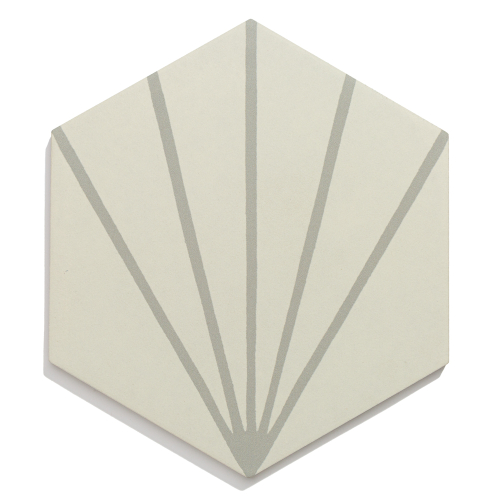

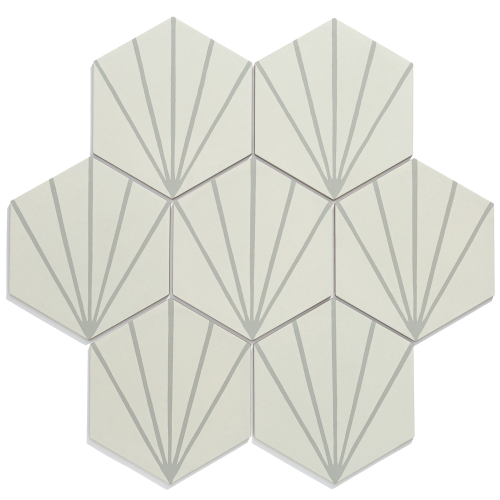

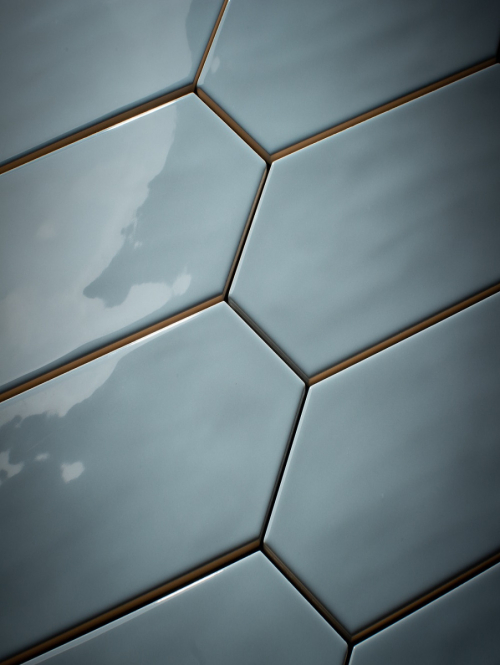

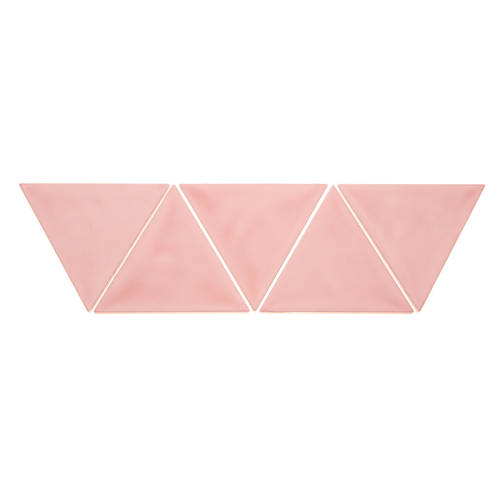

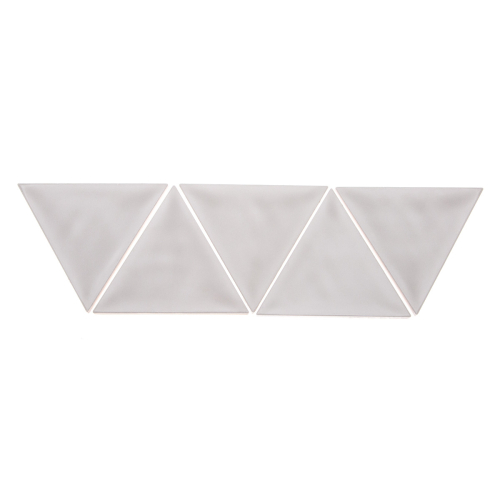

Whether you’re investing in a completely new kitchen and bathroom or going for a quick splashback update, our range of indoor tiles has all you need to make your dream space a reality. There’s everything from trendy patterned designs to country-style wall tiles and contemporary, large-format planks. What’s more, all our tiles are really durable so you can stamp personality over your kitchen without compromising on the practical.

- Huge range of tiles available

- Beautiful range of designs

- Easy to keep clean

- Splashback to XL sizes

Speak to a member of our friendly sales team today on 01482 688008 or Email sales@meltonstone.co.uk

Indoor Tiles

Porcelain tiles are an excellent choice for any room in your home. They are easy to clean and can be used in kitchens, bathrooms, and any other room in the house. There are many different styles available, so you can find something that matches your preference.

What Are Porcelain Tiles?

A porcelain tile is made from clay fired at very high temperatures 1,200 degrees Celsius. This makes it highly durable and resistant to heat damage. Porcelain tiles can also have a glossy finish that helps protect against liquid stains and marks as well as a more Matt textures finish to help with slip resistance.

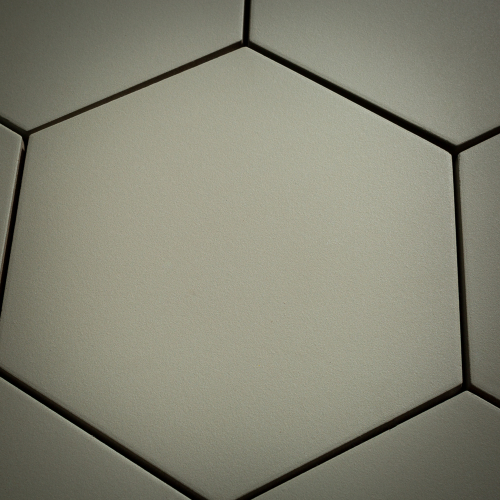

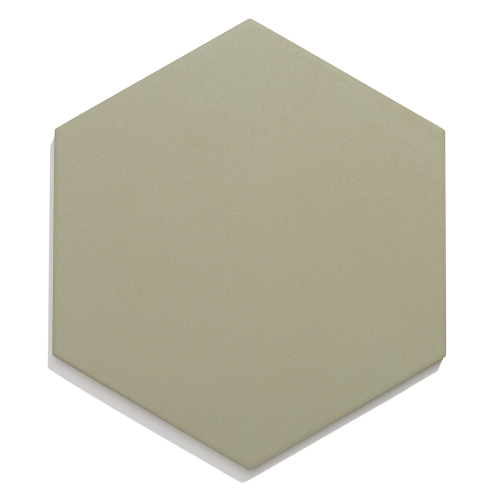

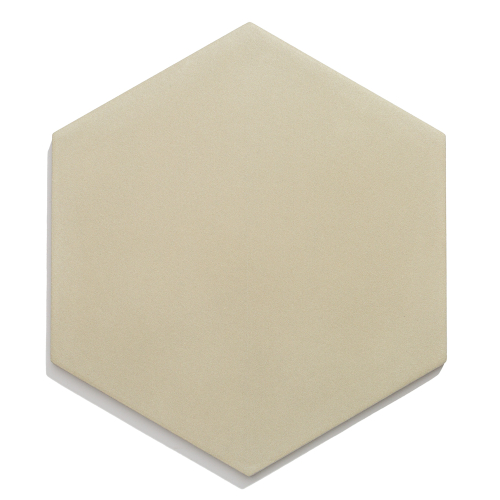

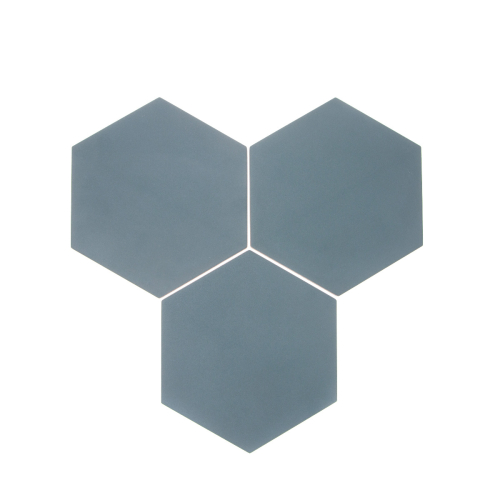

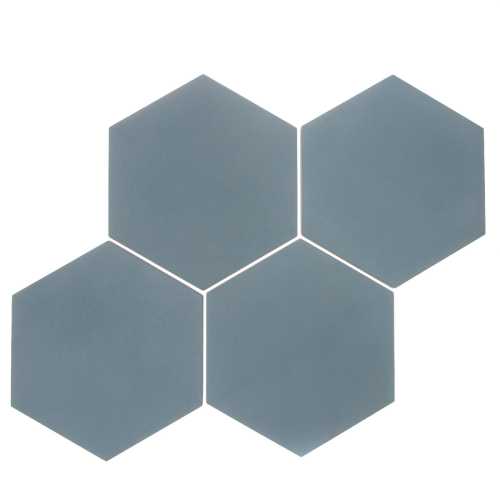

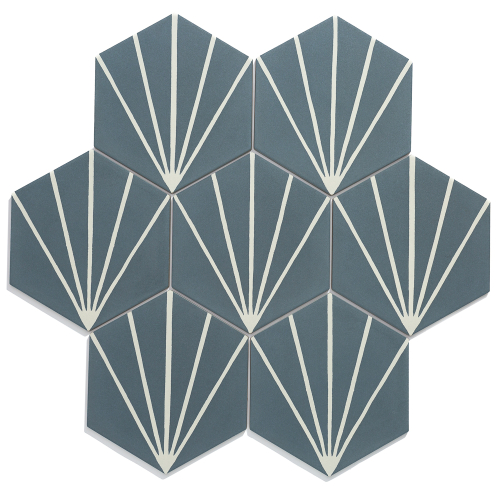

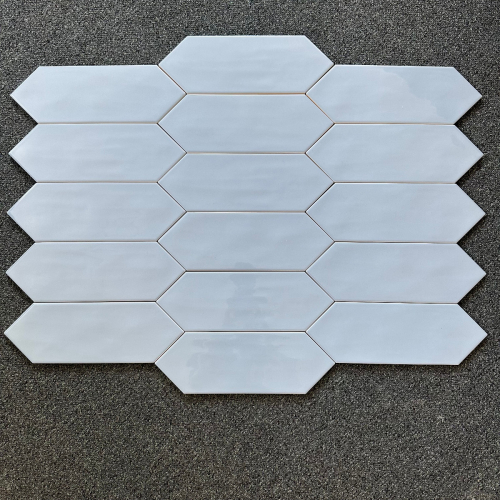

Porcelain Tiles come in a range of different size and shapes, here at Melton Stone we have multiple different ranges and we are confident that you can find something that will suit your style. They can be also used indoors and outdoors depending on their type, thickness and other features that make them suitable for specific environments.

Here are some of the benefits of porcelain tiles

Durable: Porcelain tiles are strong enough to withstand heavy traffic and regular use in high-traffic areas like kitchens and bathrooms. They offer a greater resistance against cracks, chips and scratches.

Slip-Resistant: Porcelain tiles have a textured surface on top that helps prevent wet or dry slips. This makes them ideal for bathrooms with a chance of water spills or accidents involving liquids like bathtubs or toilets.

Heat Resistance: porcelains tiles can withstand extreme temperatures without changing shape or colour, so they’re perfect for use in kitchens or bathrooms that get hot from cooking or heating appliances such as stoves and dishwashers.

Smooth Surface: porcelains tiles have a smooth surface that’s easy on the feet, so they’re ideal for use in areas where people walk barefoot, such as kitchens and bathrooms, because they won’t get cut by shards of broken glass.

How to Cut Indoor tiles

There are many ways that indoor tiles can be cut. the most popular methods are; Manual Tile Cutter, Electric Tile Cutter, Angle Grinder, Tile Nippers. The most popular method for both professionals and homeowners alike is a manual tile cutter this is because they are easy to use, creates less dust and generally a lot safer than the others. Manual Tile Cutters can also be referred as a score and snap or a rail cutter.

How to Grout Indoor Tiles

There are a couple of different options that you can choose when looking at grout for indoor tiles, rapid setting adhesive or standard setting adhesive. Along with different set times of grouts you will also have different colours that you can choose from. Generally light colour materials are ideally suited with light grout while dark colours are suited with darker colours although this is all down to personal preference.

What tile adhesive should I use for Indoor tiles?

Once you have made your tile choice you will now be wondering the best way to adhere your new tiles so that they don’t only look great they will remain that way for the years to come. There are two main types of adhesive to look out for, a ready mixed paste or a powder based adhesive, if you are fixing to the wall both options will work depending on the tile type, if you are fixing to the floor then a powder based adhesive would be the better option.

Indoor Outdoor Tiles

The indoor/ outdoor affect is starting to take the world by storm with people creating a flow between the bifold doors in the kitchen to the outdoor living space you can truly create a space that anybody will be proud of.

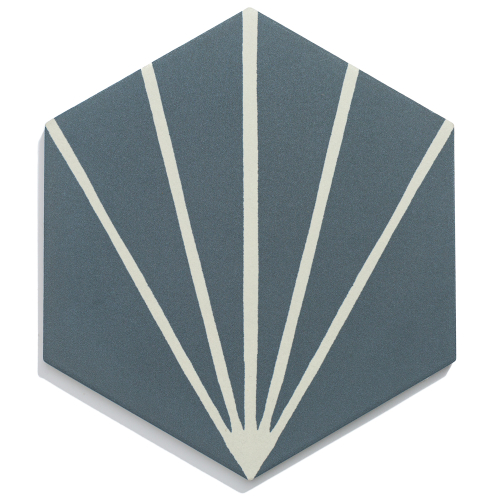

Kitchen Tiles

In most homes the Kitchen is one of the most used rooms, as we are cooking, entertaining and relaxing in here. So having a flooring that is not just practical but stylish is the way forward. Porcelain tiles are often used in kitchens because they’re easy to clean and resist stains from fruit juices or wine spills as well as any other spills that will happen in the kitchen.

Bathrooms Tiles

Porcelain tiles are ideal for bathrooms as they’re easy to clean and don’t need any special preparation before installation. They’re also waterproof so that they can be used on floors, walls and in and around your shower / bath.

Floor Tiles

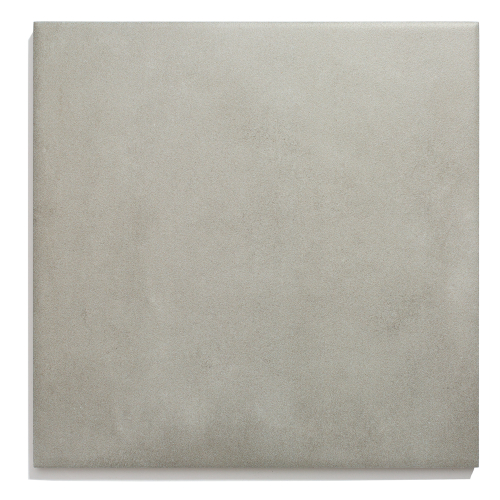

Porcelain tiles make beautiful floors. They’re durable, easy to clean and resistant to stains. They can also be used on walls and floors, here at Melton Stone we have multiple different range that can be used from a beautiful natural wood effect tile to a more rustic natural looking concrete effect tile.

Backsplash

Tile backsplashes make kitchens more functional than ever before. With so many different designs available, it’s easy to find one that matches your taste.

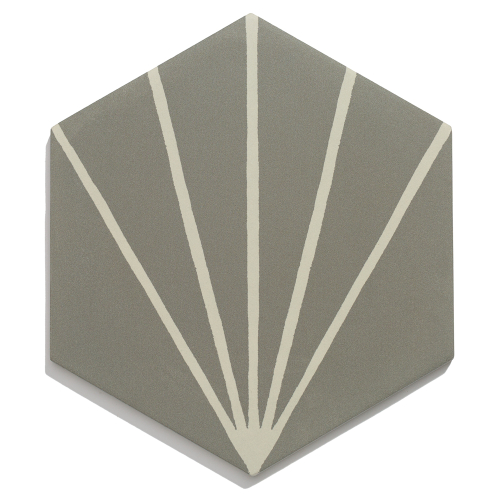

Tile Samples

With so many different options that you can choose from, we want you to love your new Indoor tiles, so why not order a sample to see these beautiful tiles in person.